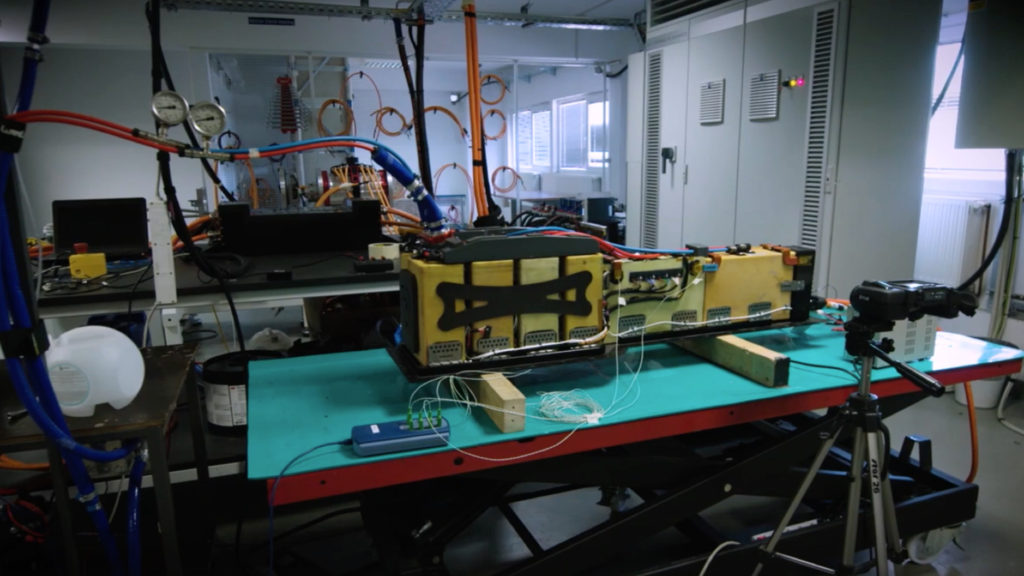

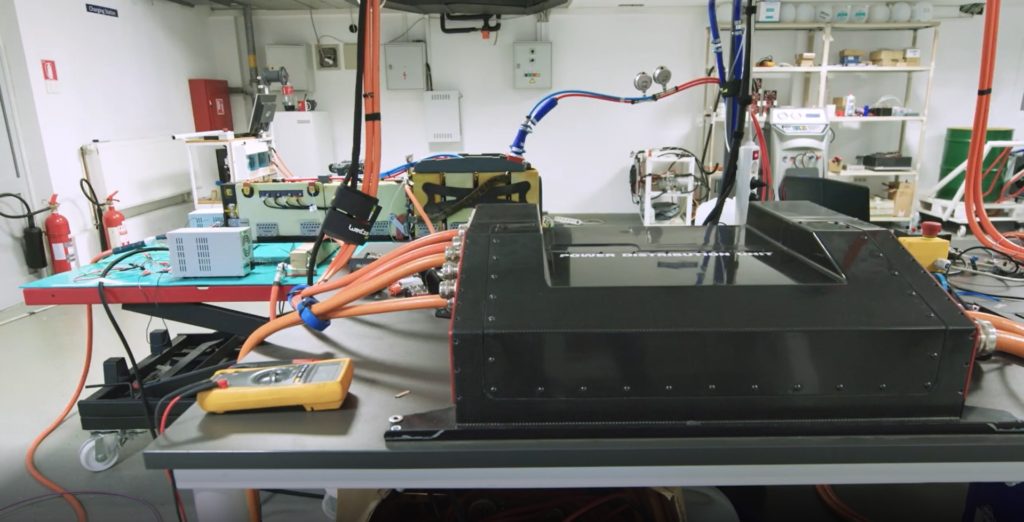

You may have seen engines test on dynamometers, but Rimac does the same thing with its batteries produced for electric hypercars. As with engine dyno testing, this guarantees the batteries meet performance objectives and handle real-world use.

The company resembles everything a battery might experience in a car, including acceleration, charging, track use, and freeway driving, CEO Mate Rimac unfolds in a video from YouTube channel Apex One. By running these simulations 24/7, engineers can more or less replicate an existence of use in a few months, he said.

Engineers can get all of the information they need while batteries sit on a test stand. While producing batteries for the Koenigsegg Regera hybrid, Rimac simulated a 0-400 kph (0-248 mph) acceleration run this way.

Throughout tests, engineers monitor many distinct parameters, including the voltage and temperature of each unique battery cell, as well as the temperature of the entire battery pack. Cells are separately selected for use in a given pack, so their features are as consistent as possible.

Any ineffective cells can be traced back to their point of origin, he added.

As with internal-combustion engines, batteries run best under very specific circumstances. Testing helps figure out what the best performing range is, Rimac said.

When a battery is discharged during testing, the electricity is sent into the grid, which has created a bit of a problem for the automaker.

In addition to producing a battery pack for Koenigsegg, Rimac will provide a pack for the Aston Martin Valkyrie, and will work with Hyundai on an all-electric N sports car. Rimac is fighting to get its own second-generation electric supercar—the C_Two—into production.